Como sabemos, la perforación proporciona la mayor parte de la información para la evaluación final de un prospecto y en última instancia, determinará si este es explotable económicamente. Uno de los métodos de perforación más conocidos es el de Perforación de Circulación Reversa (RC). A continuación, conozcamos más sobre esta forma de perforación o sondaje.

Perforación de Circulación Reversa (RC)

La perforación de Circulación Reversa o llamado comúnmente aire reverso, crea pequeños fragmentos de roca (chips) en lugar de un testigo sólido (core o núcleo). A diferencia, de la perforación diamantina, es mucho más rápida y requiere de un equipo mucho más grande, incluyendo un compresor de aire de gran capacidad.

¿Cómo funciona?

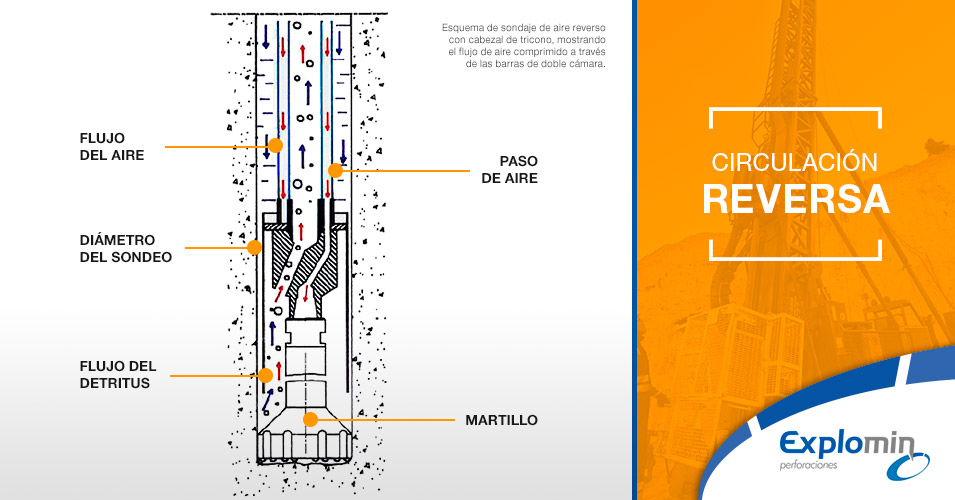

El diseño de las barras para Perforación de Circulación Reversa permite la recuperación de muestras, por el centro de ellas debido a su doble pared. El aire o agua, que son los medios más usados para el barrido, ingresan a la columna a través de las paredes de la barra o entre el espacio anular que queda entre la funda exterior y el tubo interior por medio de una conexión lateral (swivel), bajando hasta el fondo del pozo las muestras que se están extrayendo, son dirigidos hacia el centro de la herramienta de perforación y evacuados a la superficie.

Desde allí son desviados por un conducto de descarga hasta una manguera de caucho, la cual está conectada a una unidad de desaceleración de partículas (ciclón captador de polvo) y recuperadas apropiadamente para su análisis.

Las medidas de las barras de Perforación de Circulación Reversa son por lo general de 4.5″ – 7″ de diámetro y 20 pies de largo (6,096 m). Cada barra es muy pesada y requiere el uso de un manipulador de barras Rod Handler, grúa o «winche» para levantarla y colocarla sobre el pozo.

Cabezales de perforación

Los cabezales de las máquinas para Perforación de Circulación Reversa son diferentes a las brocas o coronas diamantadas (Perforación Diamantina). Un tipo de cabezal se llama martillo, el cual pulveriza las rocas golpeándolas constantemente. Este tipo de cabezal rinde eficazmente en condiciones de perforación en seco (es decir, por encima del nivel freático) y en las formaciones rocosas que son densas y duras.

Triconos

Cuando la perforación se realiza por debajo del nivel freático, el agua del subsuelo actúa como amortiguador impidiendo muchas veces la fragmentación de las rocas mediante la perforación con martillo. En estos casos se emplea el cabezal denominado tricono, el cual cuenta con tres conos dentados rotatorios que giran juntos, como el diferencial de los engranajes en una transmisión de los automóviles. Los triconos se caracterizan por su lentitud en la perforación de formaciones duras, pero son muy eficientes en formaciones blandas y en condiciones de perforación húmeda.