As we know, drilling provides most of the information for the final evaluation of a prospect and will ultimately determine whether it is economically exploitable. One of the best-known drilling methods is Reverse Circulation Drilling (RC). Next, let’s learn more about this drilling method.

REVERSE CIRCULATION DRILLING

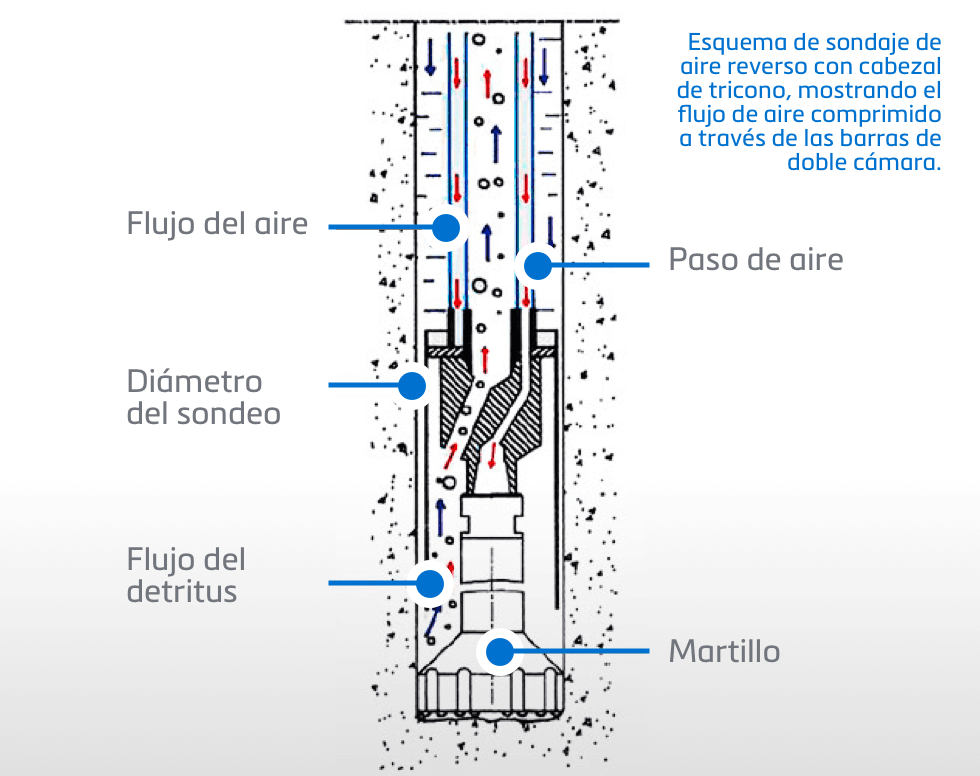

The design of the rods for reverse circulation drilling allows the recovery of samples, through the center of them due to its double wall. Air or water, which are the most used means for sweeping, enter the column through the walls of the bar or between the annular space that remains between the outer sleeve and the inner tube by means of a lateral connection (swivel), the samples being extracted are lowered to the bottom of the hole, they are rigid towards the center of the drilling tool and evacuated to the surface. From there they are diverted through a discharge conduit to a rubber hose, which is connected to a particle deceleration unit (dust collector cyclone) and appropriately recovered for analysis.

DRILLING WITH CASING ADVANCER (SUPER JAW)

One of the systems we currently use for RC drilling according to the client need is this innovative Casing Advancer Wireline system, which provides an efficient method of drilling through decomposed soils while simultaneously coating even bedrock. We use this simple system that reliably positions the casing while drilling, regardless of ground conditions. Removing and replacing the Casing Advancer Wireline is quick, easy and positive